While scrolling on Instagram, I came across something that made me stop… climbing holds Greenholds made from old ropes. My first thought? How would that feel? Do they have grip? Curiosity won, and after a few messages we decided to go and see for ourselves.

Visit to Greenholds at Ivy Climbing Gym

Our journey took us to Ivy Climbing Gym in Sittard, the home base of Greenholds headquarters. Tim welcomed us and gave us a tour of the gym. This climbing hall is different: machines to clean holds, an elevated work platform for route setters, and smart innovations everywhere. It is clear that the owners invest heavily in technology here. We then continued to the Greenholds office and spoke with Geert, the initiator and co-owner, about climbing holds, but not just any holds, holds made from ropes.

Why sustainable holds matter?

Indoor climbing is growing, and for many of us that feels like a dream come true. But there is a hidden problem that most climbers never stop to consider. Every year, millions of plastic climbing holds are produced worldwide, and almost none of them are recyclable. Why? Because chemical bonds and rough coatings make recycling impossible. Some brands make their holds from recycled plastic, but that does not mean the final hold can also be recycled later. Once a texture or coating is added, the material is no longer recyclable. The problem remains.

Greenholds decided to take action. Together with industrial partners and Zuyd University of Applied Sciences, they researched the true impact of climbing holds and how these could be made fully recyclable. After years of testing, they found the answer: polyamide (nylon), collected from industrial waste and also from old climbing ropes. No new plastic. No petroleum-based materials. No textures or coatings. A completely different production model.

How Greenholds are made?

Most climbing holds today are cast: liquid material is poured into a silicone mold and then has to cure. This takes time, and macros often require additional coatings to create texture. The silicone mold itself eventually becomes waste after dozens of casts.

Greenholds uses a different method: injection molding, the same technique used to make LEGO bricks. In this process, the material is melted and injected under pressure into a metal mold. It cools quickly and comes out ready to use, with texture built in. This makes production faster and fully recyclable. The mold itself is infinitely reusable and or recyclable.

What makes this even smarter is the design of the mold. It consists of four interchangeable parts, allowing Greenholds to create new shapes by rotating or replacing them. This keeps production efficient and sustainable, while still offering enough variation for route setters. When I asked how you create a “pocket,” the answer was simple: rotate one part and the pocket is built into the hold.

A deposit system for climbing holds

What happens to old climbing holds in your gym? Some are refurbished, others end up in storage, and many are simply thrown away. A waste, and it adds up quickly. Now imagine a different system: returning old holds, just like empty bottles. Greenholds has already made this possible with a deposit system. Gyms buy Greenholds, use them, and once they are worn out, they send the holds back and receive their deposit in return. The old holds are melted down into new ones, ready for fresh routes.

If this model grows, route setting can become far more sustainable and cost-efficient. Instead of throwing holds away, gyms can continuously refresh their walls without guilt. A simple idea with the potential to change the entire industry.

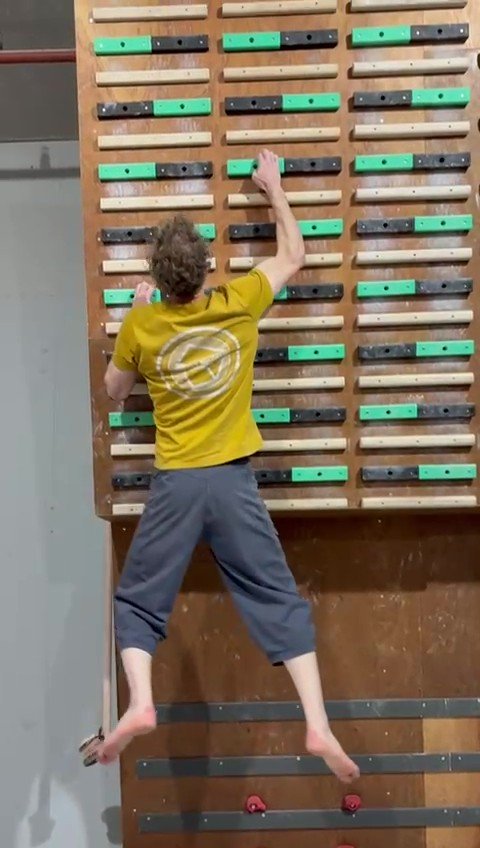

Climbing on Greenholds

Finally, it was time to climb. With a mix of curiosity and doubt, I clipped in. Honestly, I expected Greenholds to feel slippery. But the moment I grabbed the first hold, I was surprised. The texture offered solid grip and felt soft on my skin. The route setter had used them creatively, turning the route into a fun and varied challenge. The symmetry also looked good on the wall. While the current range seems best suited for route climbing, I could easily imagine a striking boulder set with these shapes as well.

I will admit it: I am picky about holds and routes. Greenholds may not have the bold, eye-catching looks of brands like Unit or Cheeta, but the climbing experience was excellent. Greenholds also adds a thoughtful touch by providing information cards to mark sustainable routes. A small gesture that helps climbers understand the story behind the holds and the values of their gym.

Final thoughts

Climbing is about freedom, movement, and a connection with nature. Those values should not disappear when we climb indoors. That is why I believe Greenholds belongs in every gym. Every set you buy is more than just a piece of equipment; it is a step toward a completely different production process. Greenholds is one of the most innovative climbing products in the Netherlands, supported by research, industry partners, and the academic world. A scientific study (publication coming soon) shows that Greenholds has no less than 90 percent less environmental impact than a conventional climbing hold.

Would you like to experience it for yourself? Visit Ivy Climbing Gym in Sittard, or purchase Greenholds directly through their website. They offer various sets, including campus rungs for home use. By supporting this initiative, we are building the future of climbing together.